Table of Contents

- Injection Molding

- Casting

- Machining

- Comparison at a Glance

- Choosing the Right Process

- Ryadon’s Global Advantage

- FAQs

Selecting the right manufacturing process isn’t just a technical decision—it’s a strategic one. For sourcing and procurement professionals, choosing between injection molding, casting, and machining can define cost, quality, and lead time across an entire product lifecycle.

At Ryadon Global Sourcing, we help customers navigate these choices every day. With over 30 years of experience and a trusted network of qualified global manufacturing partners, Ryadon provides end-to-end support—from product design and material selection to quality control and logistics—so you get parts that perform as intended, at a competitive cost.

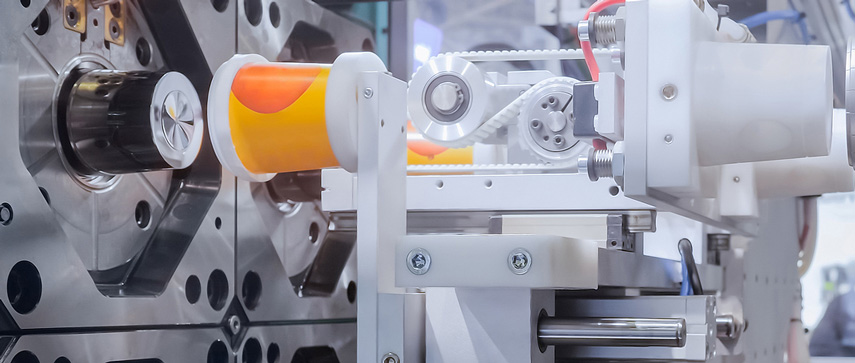

Injection Molding for Efficiency and Precision in High-Volume Production

Injection molding is ideal for producing high volumes of identical plastic parts. Molten resin is injected into a mold cavity, forming precise, repeatable components once cooled.

Best suited for:

- High-volume production runs

- Plastic and composite components

- Custom products, enclosures, or housings

Advantages:

- Low cost per unit at scale

- Tight dimensional repeatability

- Excellent surface finish and color control

- Supports complex shapes and thin walls

Tooling costs are significant upfront, but long-term savings come through efficiency and consistency. It’s a go-to method for OEMs looking to streamline production without sacrificing quality.

Common applications: Consumer electronics, appliance components, automotive interior parts, custom housings, and engineered fasteners.

Casting for Strength, Complexity, and Durability in Metal Parts

Casting involves pouring molten metal into a mold to form complex shapes once solidified. It’s widely used across industries requiring durable, high-strength parts.

Best suited for:

- Medium- to high-volume metal production

- Components requiring strength and weight optimization

- Complex geometries not feasible with machining

Advantages:

- Suitable for aluminum, zinc, and steel alloys

- Supports intricate shapes and internal cavities

- Cost-effective for large parts or volume orders

- Reduces machining time through near-net shape formation

Casting can introduce internal porosity if not tightly controlled. Partnering with a qualified foundry—like Ryadon’s vetted network—ensures consistency, minimal defects, and optimal metallurgical quality.

Common applications: Engine components, brackets, housings, wheels, and industrial machinery parts.

Machining for Precision Engineering in Low-Volume or Critical Components

Machining removes material from a solid block using cutting tools, mills, or CNC systems. It delivers unmatched accuracy and finish for parts requiring precise dimensions or special materials.

Best suited for:

- Low- to medium-volume runs

- High-precision components

- Prototyping and tight-tolerance applications

Advantages:

- Superior precision and surface quality

- Fast setup and design flexibility

- Suitable for both metals and plastics

- No tooling or mold investment required

Machining can be more expensive per unit for large quantities due to slower cycle times and material waste. However, for prototypes or small batches, it provides excellent value and quality.

Common applications: Hydraulic fittings, shafts, bushings, gear housings, and industrial fasteners.

Comparison at a Glance

| Criterion | Injection Molding | Casting | Machining |

|---|---|---|---|

| Materials | Plastics, composites | Metals (Al, Zn, Steel) | Metals, plastics |

| Best Volume | High | Medium–High | Low–Medium |

| Tooling Cost | High | Moderate | None |

| Lead Time | Moderate | Moderate | Short |

| Precision | High | Moderate | Very High |

| Design Flexibility | Low | Moderate | High |

| Surface Finish | Excellent | Good | Excellent |

Choosing the Right Process

When evaluating which process is best for your product, consider these key factors:

Production Volume

For mass production, injection molding wins. For medium runs or metal parts, casting balances cost and strength. For prototypes or custom parts, machining is the most flexible.

Material Requirements

Plastic components > Injection molding. Metal strength or durability > Casting or machining.

Design Complexity

Intricate internal shapes > Casting. Precise dimensional tolerances > Machining.

Budget and Lifecycle

Tooling-heavy methods like injection molding pay off over long runs. Machining is ideal when you need to test or refine a design first.

End-Use Environment

Consider load, temperature, and corrosion factors when selecting your manufacturing method.

Ryadon’s Global Advantage

At Ryadon Global Sourcing, our value lies in helping you make the right manufacturing choice — then managing every detail from prototype through delivery.

We combine engineering expertise, supply chain experience, and strong factory partnerships across Asia and the U.S. to ensure each project meets your cost, quality, and timing goals.

Whether you’re developing a new product or optimizing an existing component, our team will:

- Evaluate your design for manufacturability

- Match it with the right process and factory

- Oversee quality inspections and material certification

- Manage logistics and inventory for consistent supply

With decades of experience and a proven qualification process, Ryadon delivers results that balance cost efficiency with premium quality.

FAQs

How do I know which process fits my component best?

Ryadon’s engineers review your design, materials, and production goals to determine the optimal balance between cost, quality, and lead time.

Can Ryadon handle both plastic and metal components?

Yes. Our partners specialize in both plastic injection molding and metal manufacturing, including casting, machining, and stamping.

What industries does Ryadon serve?

We serve OEMs across industries such as automotive, agricultural, industrial equipment, electronics, and consumer products.

How does Ryadon ensure consistent quality across factories?

Every supplier undergoes a comprehensive qualification process, including audits, sample validation, and ongoing quality inspections.

Ready to choose the right process?

Share your drawings, estimated volumes, and target timelines to receive a manufacturability review and sourcing recommendation.

We can supply all of your sourcing needs.

Click the RFQ button, email us at sales2@ryadon.com

or call us at (949) 768-8333 for more information.

Tell us what you need and we will save you time and money.